-

Sale

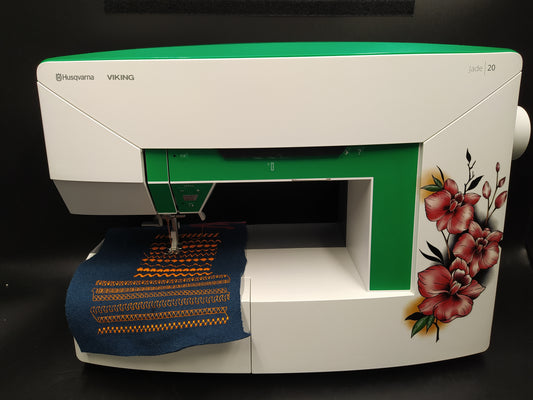

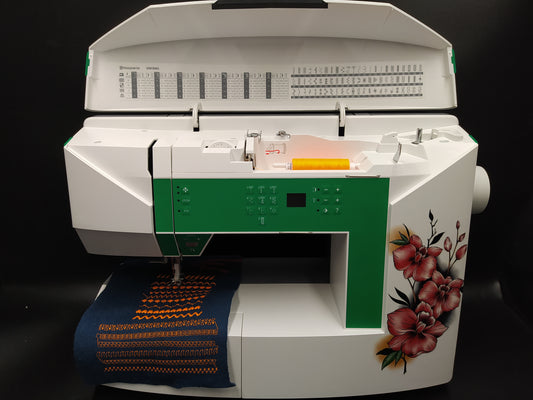

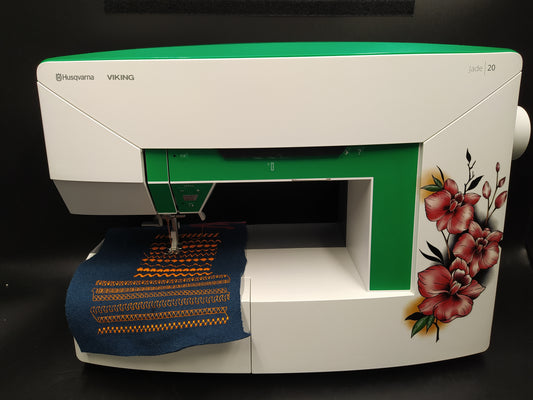

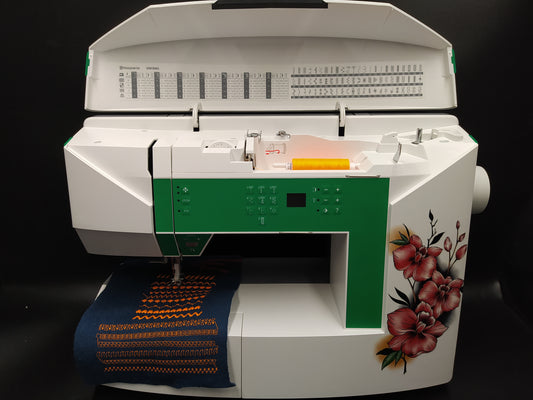

SaleHUSQVARNA JADE

Regular price 2.500,00 złRegular priceUnit price per2.750,00 złSale price 2.500,00 złSale -

VERITAS SELINA

Regular price 1.450,00 złRegular priceUnit price per -

VERITAS AMELIA

Regular price 1.100,00 złRegular priceUnit price per -

Sold out

Sold outVERITAS REGINA

Regular price 1.750,00 złRegular priceUnit price per2.350,00 złSale price 1.750,00 złSold out -

Sold out

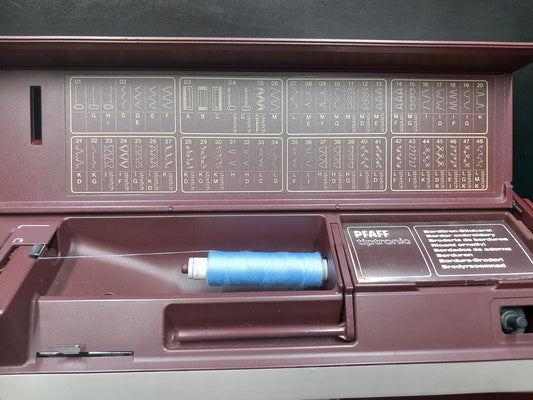

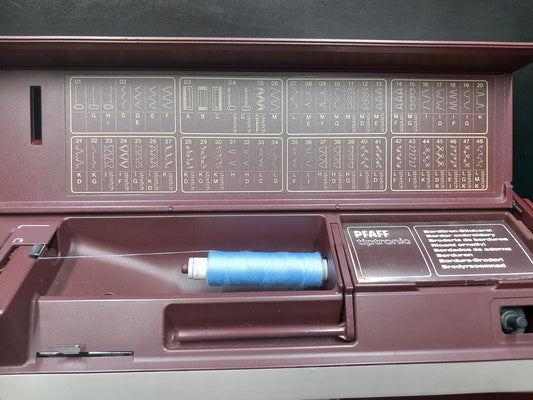

Sold outTIPTRONIC 1069

Regular price 1.200,00 złRegular priceUnit price per1.900,00 złSale price 1.200,00 złSold out -

Sale

SaleVERITAS RUBINA

Regular price 850,00 złRegular priceUnit price per1.300,00 złSale price 850,00 złSale -

Sale

SalePFAFF CREATIVE ETC

Regular price 1.950,00 złRegular priceUnit price per2.250,00 złSale price 1.950,00 złSale -

Sale

SaleSINGER 7470

Regular price 1.200,00 złRegular priceUnit price per1.450,00 złSale price 1.200,00 złSale -

Sale

SaleRUBINA'S VERITAS

Regular price 850,00 złRegular priceUnit price per1.000,00 złSale price 850,00 złSale -

Sale

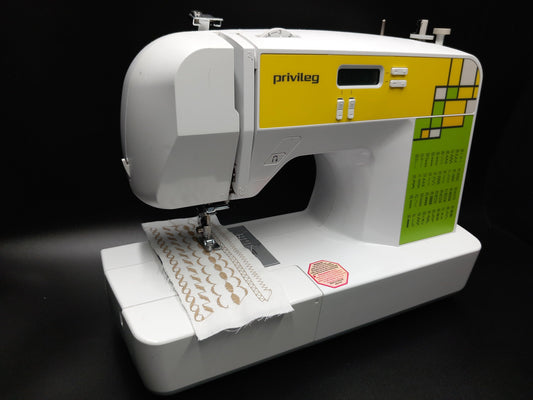

SalePRIVILEG PRO COMFORT

Regular price 1.100,00 złRegular priceUnit price per1.350,00 złSale price 1.100,00 złSale -

Sale

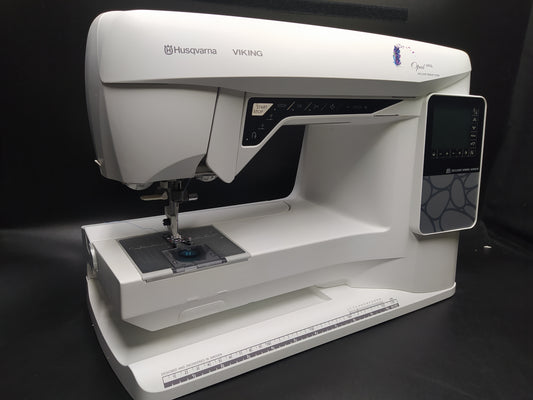

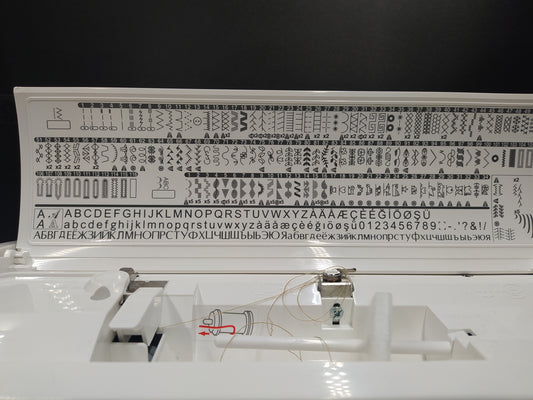

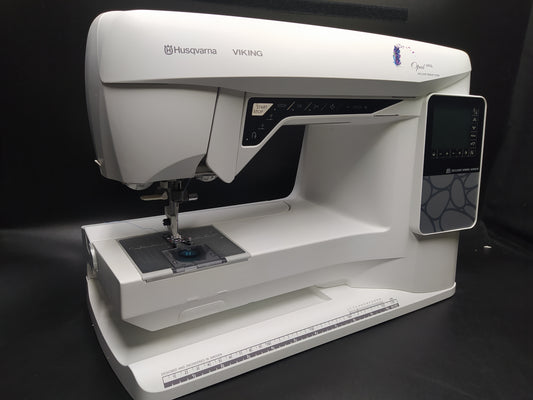

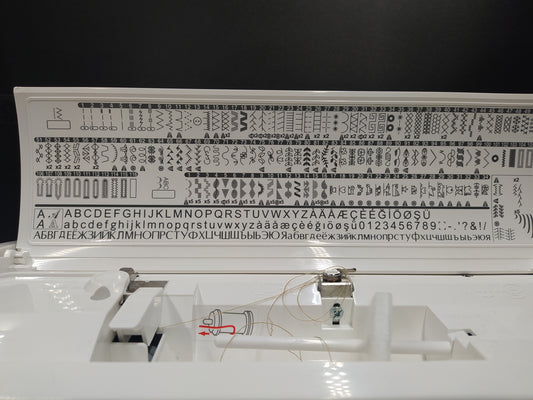

SaleHUSQVARNA OPAL 690 Q

Regular price 3.150,00 złRegular priceUnit price per3.450,00 złSale price 3.150,00 złSale -

PFAFF AMBITION QULIT ETC

Regular price 3.150,00 złRegular priceUnit price per3.450,00 złSale price 3.150,00 złSale -

Sale

SaleSINGER QUANTUM

Regular price 2.200,00 złRegular priceUnit price per2.700,00 złSale price 2.200,00 złSale -

Sale

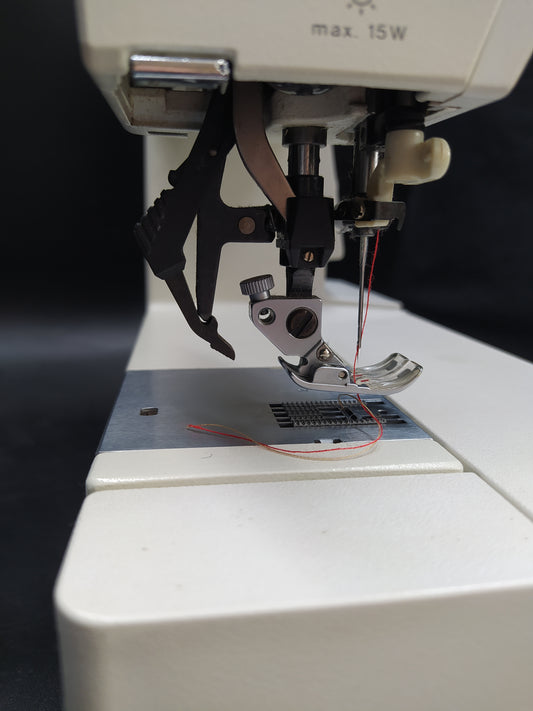

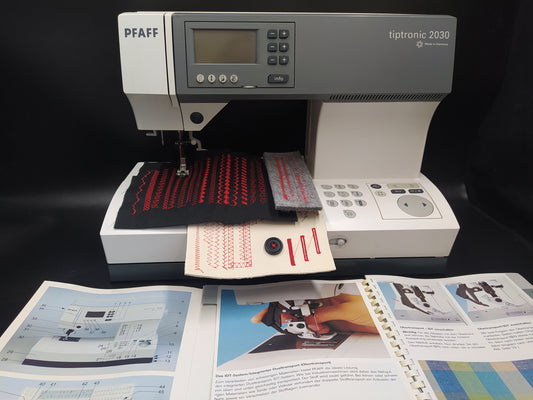

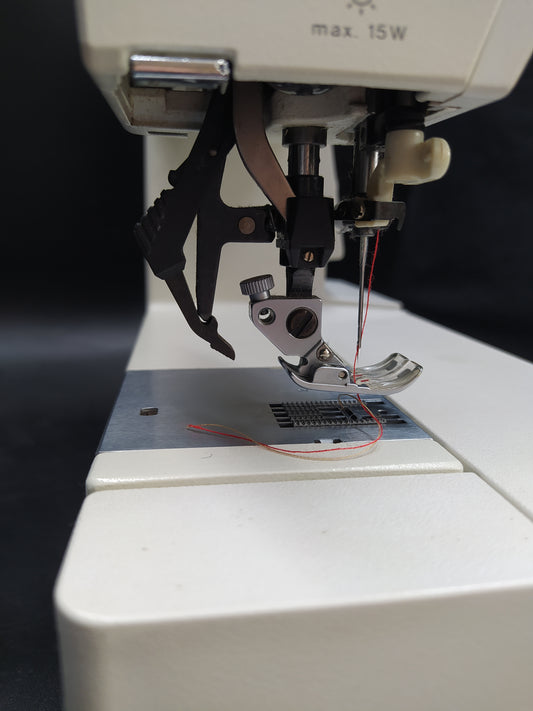

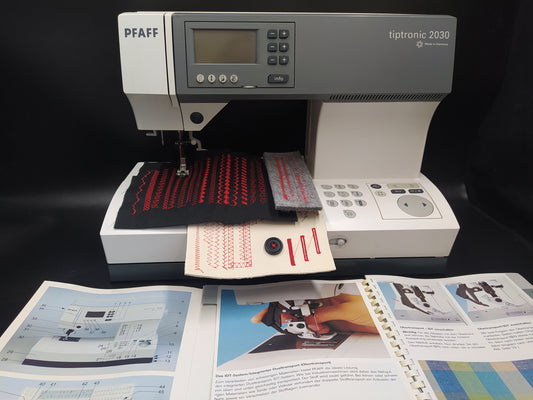

SalePFAFF TIPTRONIC

Regular price 1.950,00 złRegular priceUnit price per2.500,00 złSale price 1.950,00 złSale -

Sale

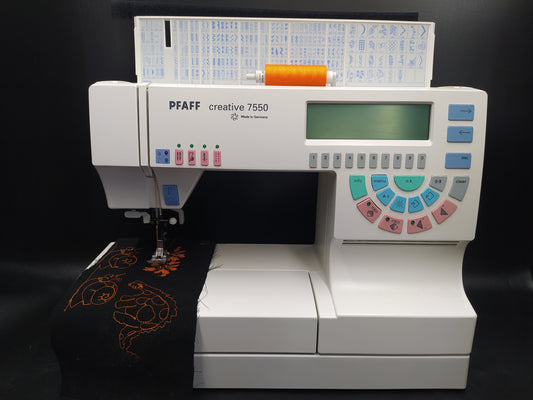

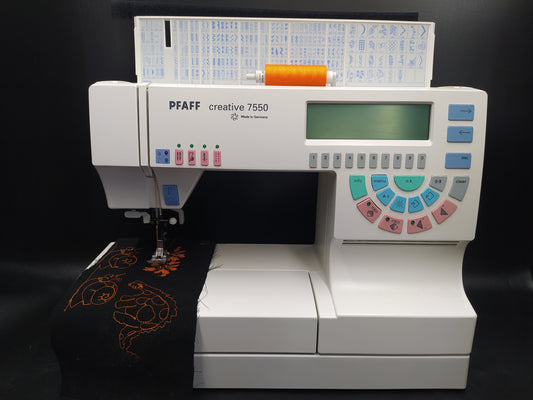

SalePFAFF 7550

Regular price 2.500,00 złRegular priceUnit price per3.000,00 złSale price 2.500,00 złSale -

Sale

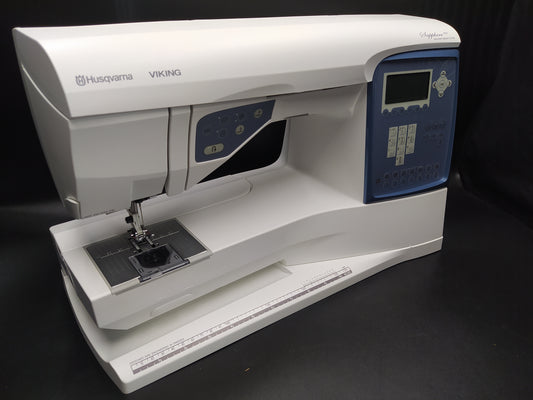

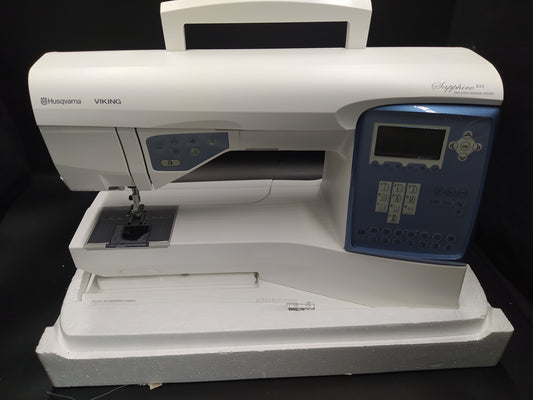

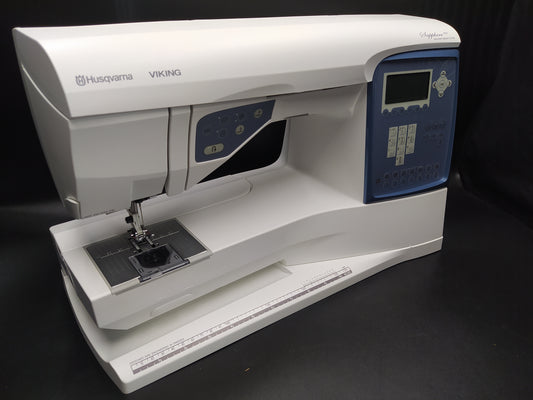

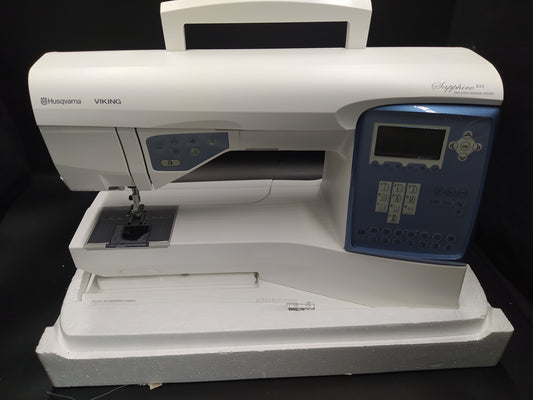

SaleHUSQVARNA SAPPHIRE

Regular price 3.150,00 złRegular priceUnit price per3.450,00 złSale price 3.150,00 złSale -

CARINA PROFESSIONAL 2

Regular price 1.000,00 złRegular priceUnit price per1.250,00 złSale price 1.000,00 złSale -

Sale

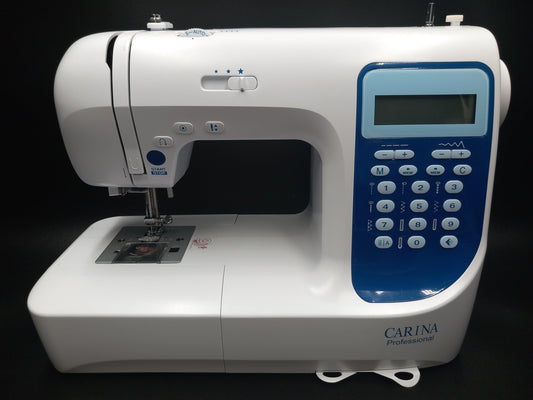

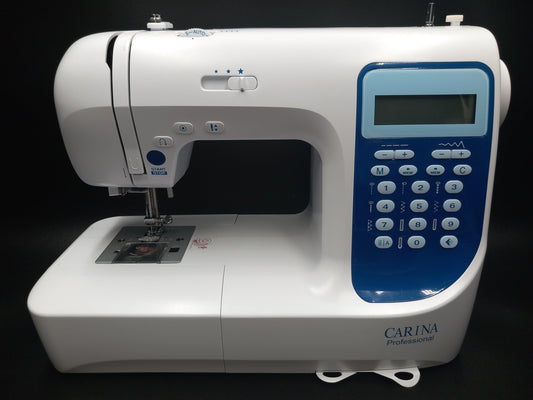

SaleCARINA PROFESSIONAL

Regular price 850,00 złRegular priceUnit price per1.100,00 złSale price 850,00 złSale -

Sale

SaleCARINA GOLD

Regular price 1.000,00 złRegular priceUnit price per1.200,00 złSale price 1.000,00 złSale